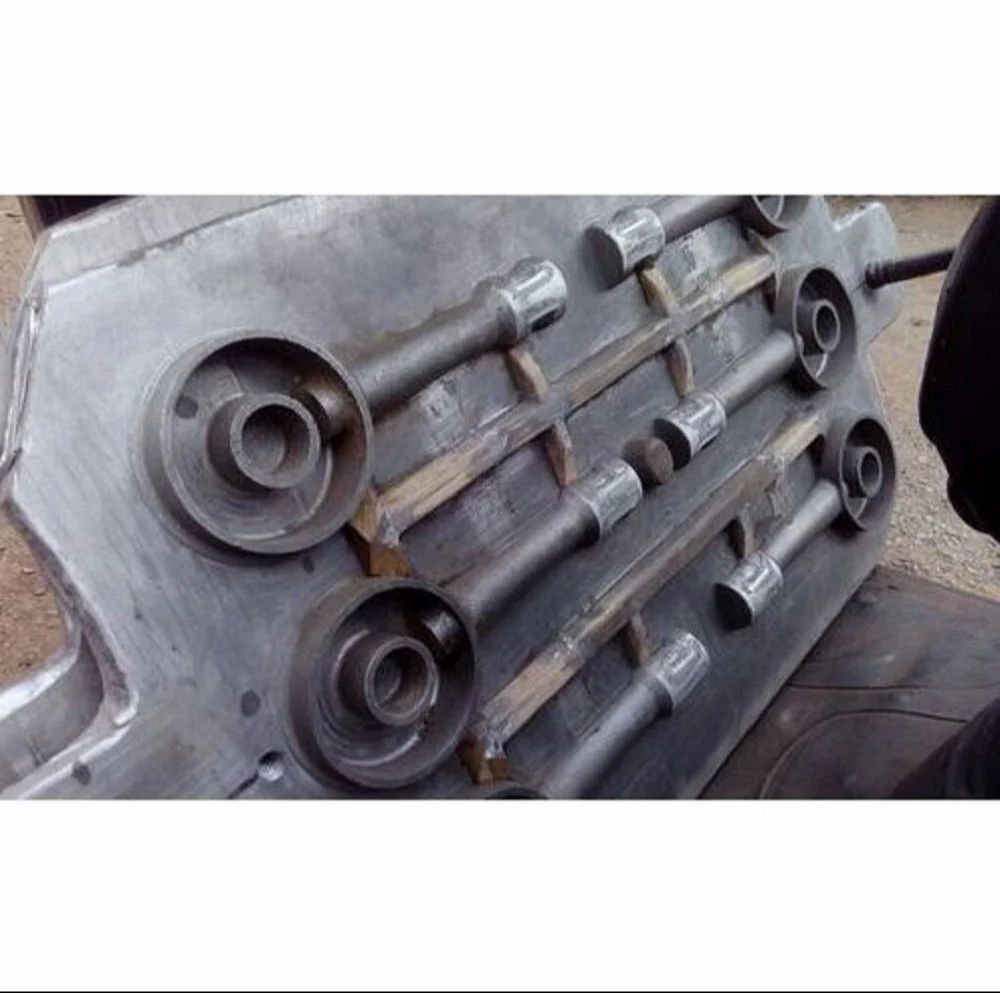

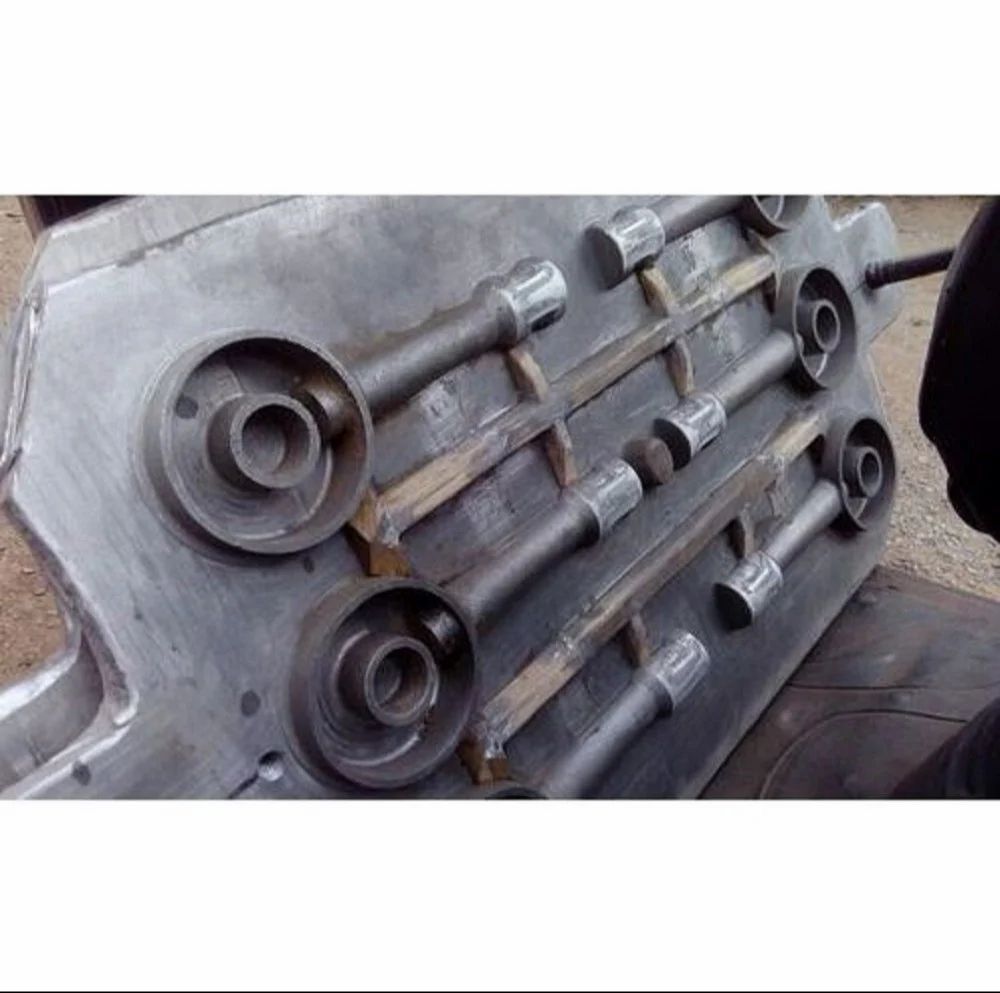

Burner Aluminium Casting

Price 27 INR/ Bottle

Burner Aluminium Casting Specification

- Usage

- lame thermal spraying torches of powder materials allow the application of various coatings on a metal surface

- Size

- nil

- Height

- nil Meter (m)

- Application

- Industrial

- Product Type

- Burner Aluminium Casting

- Surface Treatment

- Polished

- Weight

- nil Carat

- Length

- 10 Meter (m)

- Width

- nil Meter (m)

- Color

- gray

Burner Aluminium Casting Trade Information

- Minimum Order Quantity

- 20 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Burner Aluminium Casting

This Burner Aluminium Casting is used by people to cast burner with accurate diameter, hole and threading finish. When you pour molten metal into it, this product produces a burner along with maintaining high dimensional stability at extreme temperature conditions. This product is manufactured by utilizing aluminum stronger than steel with the help of dexterous professionals. We provide this product in various shapes, sizes and finishes to cater to the needs of customers in commercial and residential places. Our offered Burner Aluminium Casting is highly cherished for its good radio frequency interference (RFI) and electromagnetic interference (EMI).

Burner aluminum casting refers to the process of creating aluminum castings for burners, which are critical components in various industrial applications, such as oil and gas, power generation, and chemical processing. Here's a detailed overview:

Key Features

Lightweight and Corrosion-Resistant: Aluminum castings are ideal for burner applications due to their lightweight and corrosion-resistant properties.

High Thermal Conductivity: Aluminum has high thermal conductivity, allowing for efficient heat transfer and management in burner systems.

Complex Geometries: Aluminum castings can be designed to create complex geometries and shapes, making them suitable for various burner designs.

Applications

Industrial Burners: Aluminum castings are used in industrial burners for various applications, such as oil and gas processing, power generation, and chemical processing.

Heating Systems: Aluminum castings are used in heating systems, such as boilers and heat exchangers, where efficient heat transfer is critical.

Combustion Systems: Aluminum castings are used in combustion systems, such as fuel nozzles and combustion chambers, where precise control of fuel and air mixture is essential.

Benefits

Improved Efficiency: Aluminum castings can improve the efficiency of burner systems by providing optimal heat transfer and management.

Reduced Weight: The lightweight properties of aluminum castings can reduce the overall weight of burner systems, making them easier to install and maintain.

Increased Durability: Aluminum castings can provide increased durability and resistance to corrosion, reducing the need for frequent replacements and maintenance.

Considerations

Material Selection: The selection of aluminum alloy is critical for burner applications, with factors such as strength, corrosion resistance, and thermal conductivity considered.

Design and Engineering: The design and engineering of aluminum castings require careful consideration of factors such as thermal management, fluid dynamics, and structural integrity.

Quality Control: Strict quality control measures are essential to ensure the accuracy and reliability of aluminum castings for burner applications

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Castings Category

Bracket Aluminium Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : gray

Product Type : Bracket Aluminium Casting

Damper Aluminium Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : Gray

Product Type : Damper Aluminium Casting

Surface Treatment : Polished

Application : Industrial

Flange Aluminium Gravity Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : Gray

Product Type : Gravity Casting

Surface Treatment : Polished

Application : Industrial

BW Body Casting Aluminium

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : Red

Product Type : BW Body Casting Aluminium

Surface Treatment : Painted

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS