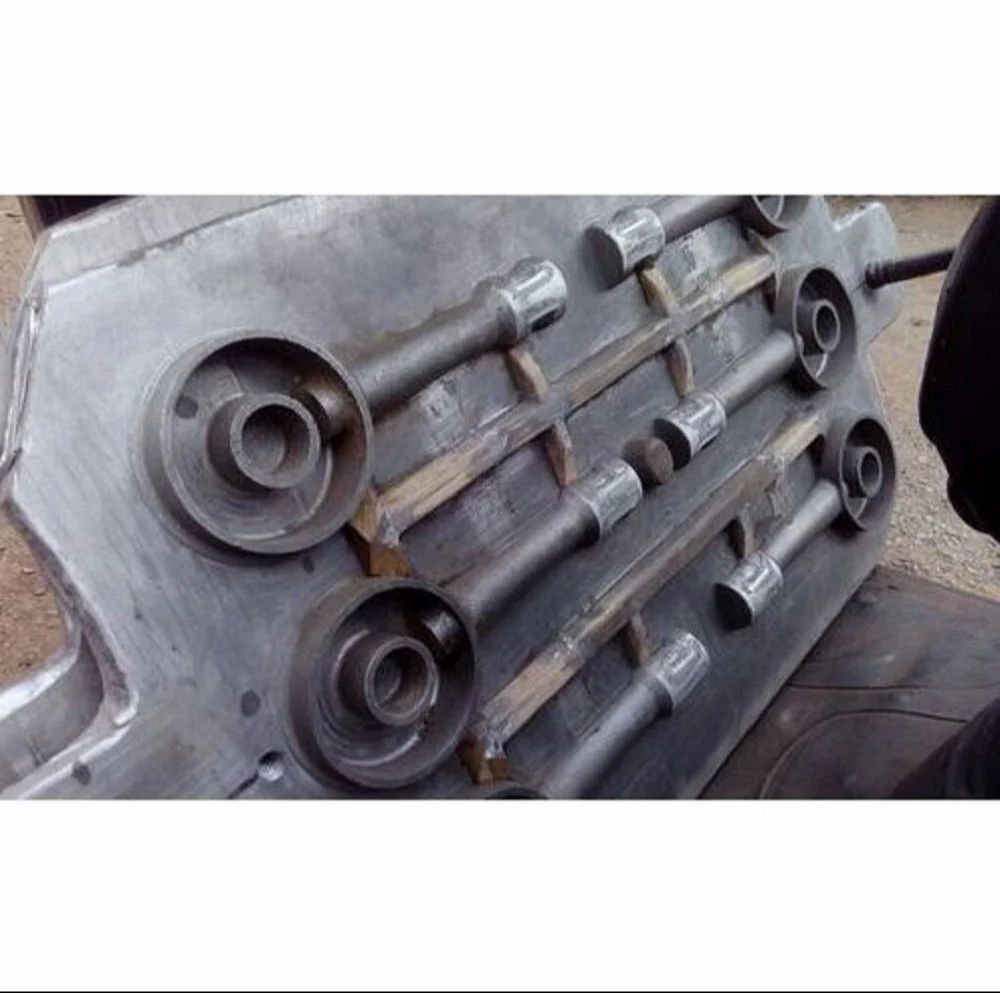

Aluminium Frame Cover Casting

Price 27 INR/ Piece

Aluminium Frame Cover Casting Specification

- Usage

- nil

- Size

- as for costmer

- Application

- Industrial

- Product Type

- Aluminium Frame Cover Casting

- Weight

- 130 Carat

- Length

- as for costmer Meter (m)

- Width

- as for costmer Meter (m)

- Color

- gray

Aluminium Frame Cover Casting Trade Information

- Minimum Order Quantity

- 20 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

About Aluminium Frame Cover Casting

Owing to its exceptional EMI and RFI shielding properties, the provided Aluminium Frame Cover Casting perfectly molds poured molten aluminum metal. To cast aluminum frame, customers extensively use this product in the foundry and forging industries. This product is known to withstand the highest operating temperatures while casting frame in a variety of shapes, sizes and designs. A recyclable feature of this product reduces the wastage of casting material and keeps it longer in use. The offered frame cover is rust resistant, rugged, electrically conductive and simple to use. This Aluminium Frame Cover Casting is manufactured in different specifications by implementing contemporary molding methods.

Aluminum frame cover casting refers to the process of creating aluminum castings for frame covers, which are used to protect and enclose various components or systems. Here's a detailed overview:

Key Features

Durable and Strong: Aluminum castings are known for their high strength-to-weight ratio, making them ideal for frame covers that require durability and structural integrity.

Corrosion Resistance: Aluminum castings can provide excellent corrosion resistance, depending on the alloy and surface treatment used, ensuring the longevity of the frame cover.

Complex Geometries: Aluminum castings can be designed to create complex geometries and shapes, allowing for customized frame covers that fit specific applications.

Applications

Industrial Equipment: Aluminum frame cover castings are used in industrial equipment, such as machinery, pumps, and motors, to protect internal components and provide a safe working environment.

Automotive: Frame covers are used in the automotive industry to protect components like engines, transmissions, and electrical systems.

Aerospace: Aluminum frame cover castings are also used in aerospace applications to provide lightweight and durable protection for sensitive components.

Benefits

Protection: Frame covers provide protection for internal components from environmental factors, dust, and debris.

Aesthetics: Aluminum castings can be designed to provide a visually appealing and professional appearance for frame covers.

Lightweight: Aluminum castings are lightweight, making them ideal for applications where weight reduction is crucial.

Considerations

Material Selection: The selection of aluminum alloy is critical for ensuring the desired mechanical properties and performance of the frame cover casting.

Design and Engineering: Careful design and engineering are necessary to ensure that the frame cover casting meets the required specifications and performance criteria.

Surface Treatment: A surface treatment, such as powder coating or anodizing, can be applied to aluminum castings to enhance corrosion resistance and provide a durable finish

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Castings Category

Burner Aluminium Casting

Price 27 INR / Bottle

Minimum Order Quantity : 20 Pieces

Product Type : Burner Aluminium Casting

Application : Industrial

Color : gray

Surface Treatment : Polished

CW Body Aluminium Casting

Price 27 INR / Bale

Minimum Order Quantity : 20 Pieces

Product Type : Casting

Application : Industrial

Color : gray

Surface Treatment : Polished

Aluminium Gravity Casting

Price 30 INR / Piece

Minimum Order Quantity : 200 Pieces

Product Type : Aluminium Gravity Casting

Application : Industrial

Color : Gray

Surface Treatment : Polished

Aluminium Corona Ring Casting

Price 27 INR / Piece

Minimum Order Quantity : 20 Pieces

Product Type : Aluminium Corona Ring Casting

Application : Industrial

Color : Gray

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free